ABOUT

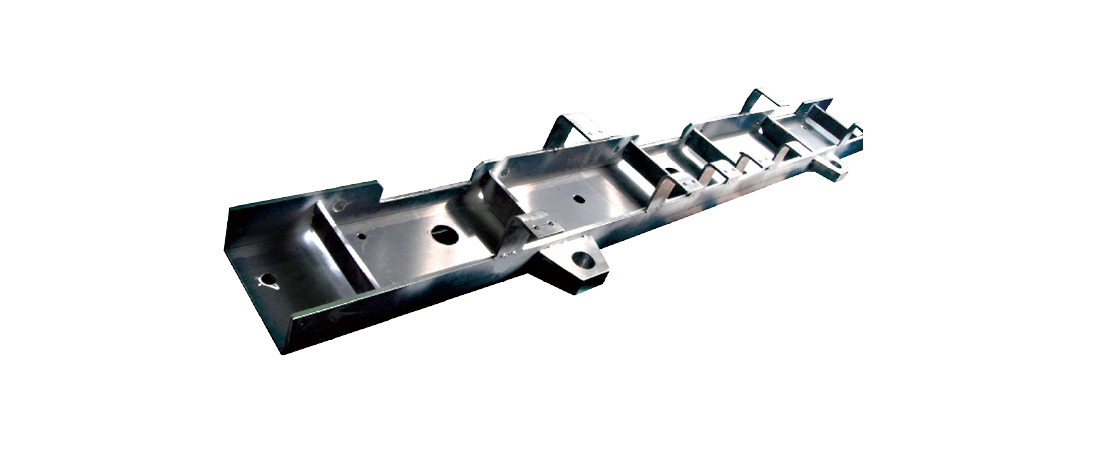

We perform iron plate drilling and bending using NC equipment, and arc/TIG welding by skilled workers. A variety of product processing is possible through a combination of accurate and efficient processing of thin plates by machines with manual work considering the degree of penetration and distortion occurrence of thin plate to thick plate welded parts.